The Important Relationship between Efficiency and Ratio in Worm Gear Reducers

In manufacturing environments, the need for efficiency and performance optimization remains a driving force for many businesses. Understanding gear reducer efficiency is crucial for engineers and designers aiming to maximize system performance.

Worm Gear Reducer Efficiency: Ratio, Run-In and Input Speed

In a recent paper published by Machine Design, Rob Holdsworth, Engineering Manager at Winsmith, explores the relationship between efficiency and gear reduction ratios of worm gear reducers. Understanding the factors that influence the performance of worm gear reducers will lead to more cost-effective and efficient designs.

The paper examines the intricacies of how factors such as run-in periods and input speeds can significantly impact the overall efficiency of these gear systems. This knowledge is pivotal, especially in applications where energy efficiency translates directly into cost savings and sustainability. Additionally, the research utilizes experimental data and advanced modeling techniques, offering a comprehensive perspective on how to enhance the lifespan and reliability of worm gear systems. By shedding light on the interaction between design parameters and operational conditions, the paper serves as a valuable resource for engineers looking to push the boundaries of worm gear applications.

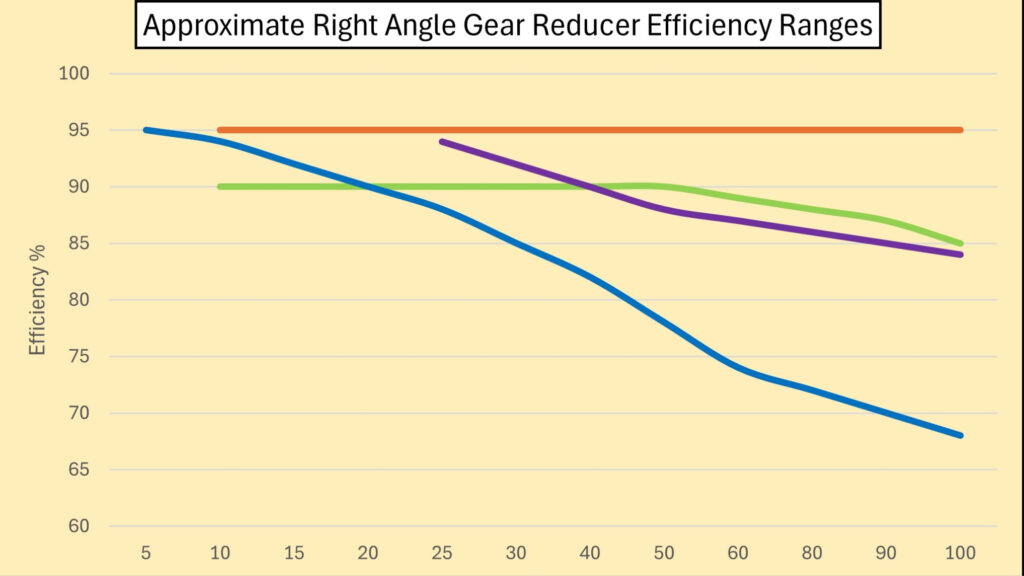

Gear reducer efficiency has always been and continues to be a primary consideration for designers in the power transmission industry. It’s important to understand that various types and ratios of right-angle gear reducers can result in significantly different levels of efficiency.

The worm gear data in the chart is from Winsmith’s SE Encore catalog. Like most competitive worm gear reducers, this product line utilizes a hardened steel worm running against a bronze worm.

To access the detailed findings and methodologies of this research, see the full article on machinedesign.com

“ Worm gear efficiency is highly dependent on reduction ratio”, said Rob Holdsworth, Winsmith Engineering Manager. “Winsmith’s rugged, single-stage worm gear reducer efficiencies of 90% or higher are very comparable to helical bevel reducer efficiencies at ratios of 20:1 and less.”

Rob Holdsworth is the Engineering Manager at Winsmith. He has been with Winsmith for the past 17 years and has more than 30 years of experience in the automation and power transmission industries.

About Winsmith

Founded in 1901, Winsmith (www.winsmith.com) produces custom reliable, high-quality solutions with millions of product configurations at US facilities in Springville, NY, Flowery Branch, GA and Asheville, NC. Winsmith designs and creates gearboxes to exceed the highest industry standards with our exceptional team of engineers, technicians and experts who drive our mission to deliver gearing solutions. Winsmith is a business of HBD Industries, Inc.